Please note you can post a comment to any image, and it will be monitored and added if verified. If you type in a comment you must go to the bottom of that specific page and verify the post by doing a quick image test. This proves you are an actual person and not a hacker remotely automatically “spamming the site”. Thank you.

This page shows the history of Mining in our local area, much sadly now long gone but still there are features still visible today if you look.

Some pictures are of poor quality but better than not having them. Hope you agree.

Wheal Goshen Mine: (No Photos) Latitude & Longitude Ref 50.309444, -5.164444

References:Wheal Goshen was a small lead mine near Goshen farm, just west of Wheal Mithian across the parish boundary. On Brenton’s map of the Chiverton Mining District, dated 1869, this mine is indicated as George the Fourth Mine. (Courtesy of mindat.org web site)

Spargo, T. (1865): The Mines of Cornwall and Devon: Statistics and Observations. Victoria Press (London), 188 pp.

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 493 (see also corrigenda in the 1994 reprint, p. xlviii).

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 48SW.

Perran Wheal George Mine: (No photos) Latitude & Longitude Ref 50.317778, -5.160833

Perran Wheal George was a small copper and lead mine, variously known as Perran Wheal George, Wheal St George, and Perran Wheal Alfred. It was first known around 1819 under the name of Perran Wheal Prosper when it was working a copper lode from shallow levels, and renamed when it was restarted in 1851.

The sett includes two ENE-trending copper lodes, about 170 yards apart, and a lead lode. The old workings from the first period of activity are on the southerly copper lode. They can be traced at the surface, but are not shown on later mine plans which only indicate workings on the northerly copper lode. The latter was opened up by four shafts, the burrows of which can still be identified in the fields adjacent to Higher Penwartha farm. There are no records of output. Note: Not to be confused with the Perran Great St George Mine near Perranporth. (Courtesy of mindat.org web site)

References:

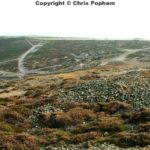

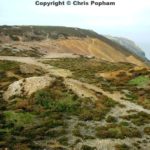

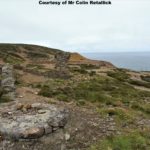

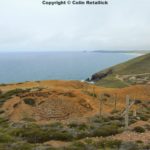

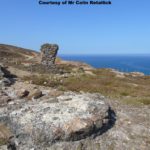

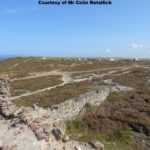

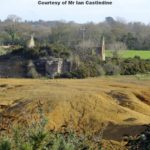

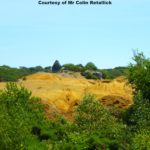

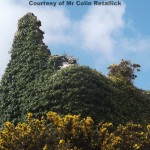

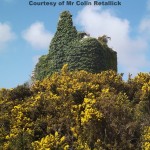

Lambriggan Mine: Latitude & Longitude Ref 50.316595, -5.146865

An unique example of a mine ore pile left standing at surface. One of very few sites of its kind in Cornwall. (Courtesy of aditnow.co.uk web site)

References:

Perran Wheal Vyvyan Mine: (No photos or info)Latitude & Longitude Ref 50.3025, -5.15953

Trevellance Mine, Bolingey: (No photos or info) Latitude & Longitude Ref 50.331078, -5.143606

Perran Wheal Jane Mixed Mine: (No photos or info) Latitude & Longitude Ref 50.3305, -5.15296

South Wheal Leisure Mine: (No photos) Latitude & Longitude Ref 50.331862, -5.147875

South Wheal Leisure was a small copper mine, also known as Truro Consols, on the western slopes of Penwartha Coombe, southwest of Bolingey. In 1871, it was worked under the name of Perran Wheal Kitty, and in 1852, it was amalgamated with nearby Perran Wheal Jane under the name of Perran Wheal Jane Consols.

The mine worked on two lodes, which carried copper ores and pyrite. The northern lode also carried some sphalerite. They were opened up by an adit along the southern lode, and by a shallow shaft. In 1911, the property was tried for tin, and 3.5 tons of black tin were raised while development works were undertaken. Another trial in 1930 was not successful. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 491-492 (see also corrigenda in the 1994 reprint).

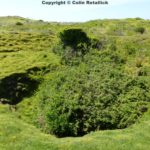

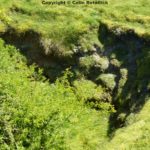

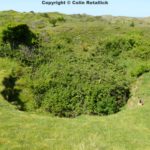

New Wheal Leisure Mine: Latitude & Longitude Ref 50.337364, -5.144022

New Wheal Leisure was small zinc and copper mine, working two EW-trending lodes, called North Lode and South Lode, below Bolingey village. South Lode was opened up by a shaft, while North Lode was accessed by an adit which commenced in the alluvial tract east of the village and followed the lode westwards for 66 fms, then turned south and connected with the workings on South Lode. A large overgrown burrow remains in the angle between Hendrawna Lane and Chapel Hill Road which marks the site of the shaft. Another large dump is located a little further east, on the opposite side of Hendrawna Lane. The dressing floors and mill noted by Hamilton Jenkin in 1956 have meanwhile been removed.

The mine raised small quantities of lead and copper ores, but sphalerite was the predominant ore mineral in the lodes. During its last period of activity, from 1907 until 1911, it produced 1,624 tons of 37% zinc ore. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 491.

Reen Wollas Mine: (No photos) Latitude & Longitude Ref 50.342007, -5.138705

Reen Wollas Mine was a small and old mine, with which Hamilton Jenkin associates two shafts that were located in a field just west of Lower Reen hamlet. Today, there are no traces of the workings left. (Courtesy of mindat.org web site)

Reference:

East Wheal Leisure Mine: (No photos) Latitude & Longitude Ref 50.331862, -5.147875

East Wheal Leisure Mine in 1833, 1851 and 1852, the mine produced 700 tons of 5% copper ore. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 450-451.

Wheal Friendship Mine: (No photos) Latitude & Longitude Ref 50.332222, -5.161944

Wheal Friendship, also known as Wheal Blandford, worked in a small way on two ENE-trending lodes crossing the valley of Perrancoombe northeast of Anchor hamlet. The northerly lode was tried by two adits on either side of the valley, the southerly by a line of surface workings along its strike. Dines also notes several lines of surface pits in N-S directions that were probably dug in search for the lodes, but these cannot now be identified. The nature of the lodes is not known, but they are believed to have been carrying tin and copper ores. There also are no records of output.

The sett included another small mine, variously known as Treslow Mine or Polglaze Mine, which was located further west, across the B3285 road, and has now disappeared below the airfield. The grid reference is arbitrarily centered in the western part of the Wheal Friendship sett. There are no traces of the mine workings left at surface. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 492.

Susan Tregay’s Droke: (No photos) Latitude & Longitude Ref 50.337805, -5.160919

A name given to a weathered ditch that was used to carry the water pumped from Devonshire shaft of Perran Great St George Mine down to the stream at Perran Coombe. According to Hamilton Jenkin, this ditch is probably an old opencast working in a stanniferous elvan. (Courtesy of mindat.org web site)

Reference:

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 48NW.

Perran Coombe Stamps: (No info) No Grid Ref

Perran United Mine: (No photos or info) Latitude & Longitude Ref 50.340576, -5.158292

Wheal Leisure Mine: (No photos or info) Latitude & Longitude Ref 50.343333, -5.151389

References:

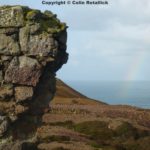

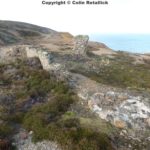

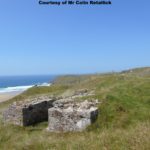

Wheal Prudence Mine: Latitude & Longitude Ref 50.331667, -5.182778

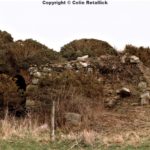

Wheal Prudence was an old copper mine located on the cliffs to the south and south-west of Hanover Cove. Wheal Prudence forms an amalgamation of the small and older Wheal Jacka, Wheal Cock and Wheal Meadow mines, although the precise locations of these old setts cannot now be determined.

The base of the 70-inch pumping engine house on New Engine Shaft still survives although the shaft itself is choked at the surface. The engine house survived in good condition until its destruction during the construction of the Second World War airfield at the site.

Other shafts can still be seen close to the cliff edge and on the coastal slope.

There are two principal lodes recorded being North (or Prudence) Lode and South (or New) Lode, there are also references to a Wheal Cock Lode and a Caunter Copper Lode.

Records indicate a production of some 7000 tons of copper ore between 1821 and 1865, with 55 tons of tin produced in 1825-6 and a further 1 ton of tin in 1847-9. (Courtesy of mindat.org web site)

References:

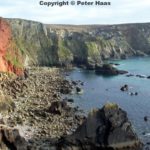

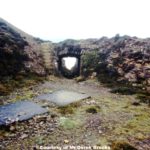

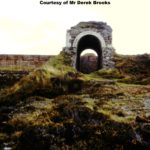

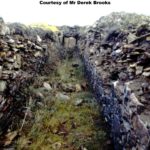

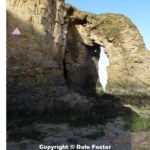

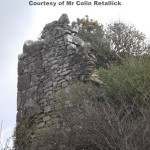

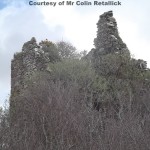

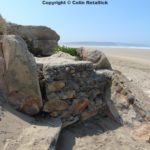

Island Shaft – Wheal Prudence Mine: Latitude & Longitude Ref 50.333611, -5.180278

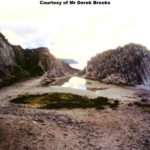

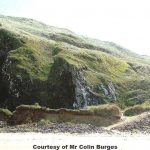

Island Shaft was an isolated working of Wheal Prudence on a rock pillar that is detached from the cliff. A wooden bridge once connected the workings to the cliff edge. In the cliff face, erosion and subsequent collapses have revealed the old workings. What looks like trials at the foor of the cliff (south of Hanover Cove) are really erosion caves (Henwood, 1843). (Courtesy of mindat.org web site)

Reference:

Henwood, W.J. (1843): On the Metalliferous Deposits of Cornwall and Devon. Transactions of the Royal Geological Society of Cornwall 5, 1-386.

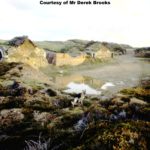

Hanover Cove Mine: Latitude & Longitude Ref 50.334575, -5.180384

Hanover Cove a small cove, earlier known as Vugga Hayle, which owes its name to the Falmouth packet ship “Hanover” that wrecked there on 2 Dec 1784. Rock falls on the cliff south of the cove have exposed part of the workings of Wheal Prudence, whose shafts are located on the cliff egde.

To access the cove, which is located about 1/2 a mile south of Cligga Head, one has to walk around the corner of the cliff at the south end of the beach adjoining Cligga Head. This is only possible at lowest tide, and when the sea is calm.

Note:

The coastal stretch between Cligga Head and the cliff that separates the beach from Hanover Cove forms part of the Cligga Head locality. The mineralization of the lodes that crop out along the beach is the same or at least similar to that found in the lodes at Cligga Head and in the vicinity of Cligga mine. Though, Hanover Cove is a separate locality with a different mineralization. (Courtesy of mindat.org web site)

Reference:

Ansermet, S. (2007): Kupfermineralien von der Hanover Cove am Cligga Head, Cornwall. Lapis 32(2), 25-26, 50. (in German)

Good Fortune Mine: (No photos or info) Latitude & Longitude Ref 50.336389, -5.171944

Cligga Head: Latitude & Longitude Ref 50.338056, -5.180556

Granite-related mineralization. Cligga Head granite is intruded in Devonian metasediments. The granite is cut by greisens-bordered NE vein-system. The greisens are cored by Sn-W-As-quartz veins. Sulfide mineralization occurs in fractures cross-cutting Sn-W-As-quartz veins. The granite is rimmed by a tourmalinite alteration aureole. Hydrothermal activity : 350-400°C, 0.7 (boiling)-1.7 kb. Na-K-Fe-Ca chloride brines rich in B, F, SO4 (degassing of magmatic volatiles).

This locality includes – Cligga Mine, which is listed as a sub- locality – the exposure of the greisen-sheet vein stockworks (another SSSI, so keep hammers in bags!), located just below the 1940s mine works on the top of the cliff, and – the beach, with numerous vein outcrops and scattered material from cliff falls.

The beach at the entrance to the mine yields arsenopyrite, cassiterite, small scorodites and wolframite without having to look too hard. More minerals are found on the beach around the cliff past the mine entrance, which extends about 1/2 mile farther south. Around the cliff at the southern end of the beach is Hanover Cove (see separate entry), which can be accessed only at lowest tide. (Courtesy of mindat.org web site)

References:

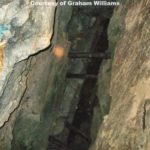

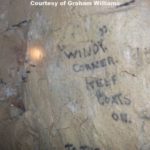

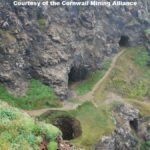

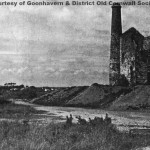

Cligga Mine: Latitude & Longitude Ref 50.338889, -5.177778

Cligga Mine workings are located on the cliff edge at Cligga Head. Just northeast of the greisen-sheet vein stockworks, and on the same level as those, is an extensive dump packed full of arsenopyrite, wolframite, iron & copper minerals. Note, however, that some of these dumps are from the Perran Great St George and Good Fortune mines, as are the workings further inland, west and north of the airfield that is now used by a glider club.

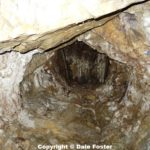

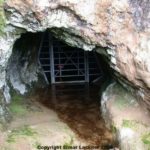

The mine itself can be accessed through the adit at beach level. The frequent rock slides have exposed some of the mine workings in the cliff face; they can be reached by climbing up inside the mine from adit level. (Courtesy of mindat.org web site)

References:

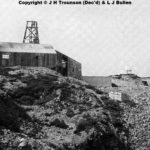

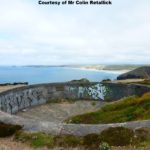

Nobel’s Explosives Factory Cligga:

When walking on Cligga, remember these people:

EXPLOSION AT CLIFFTOP WORKS. BLAST FELT AS FAR AS TRURO – 3 DEAD: British and Colonial Explosives factory was established in 1889 and shares issued. St Georges copper mine was reopened and worked near to surface. Crushing stamps for dressing the ore and also buddles were set in place.

The burning house to clean the ore was nearby. A generator provided electricity. This was a rather heavy handed affair, because the company fenced off the cliff path much to the disgust of the locals who were already enraged at having an explosive works so close by.

A licence was issued in 1891 for production with nitro glycerine to begin. When Nobel’s took over the factory in 1893, there were 80 employees. More to enrage the locals, a traction engine was used to pull three trailers, damaging the road to Cligga.

More trouble was to come. On 18th Jan.1902 three men were ‘tramming’ trucks of 500 lbs of nitro glycerine, it reached a set of points and exploded, blowing them to shreds, a man and horse were 4m away. The horse dropped dead but had been a buffer to the man who survived. Another, blown through a door against heavy metal was badly injured.

Truro reported rattled windows. The factory was put under a care order and languished until WW1. The workers filled grenades and shells for the Western front. Many locals were among 1000 people doing their bit for the great war. Closure was inevitable as war ended.

Account courtesy of Mrs Eileen Carter.

Perran St George Mine: Latitude & Longitude Ref 50.340278, -5.168056

Perran St George shafts are situated to the east of Cligga Head. An ancient mine originally worked for tin, Great St George Mine was first mentioned in 1589. Mining for copper in the area was occurring in the late 18th C, between 1800-04, Great St George Mine raised 1507 tons of copper ore (149 tons copper metal), selling for £14559. However, By 1812, the mine was returning small amounts of ore. (Courtesy of mindat.org web site)

Wheal Perran Mine: (No photos or info) Latitude & Longitude Ref 50.343889, -5.16111

Wheal Droskyn Mine: Latitude & Longitude Ref 50.347500, -5.157222

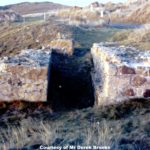

Wheal Droskyn Mine was an ancient and extensively worked mine. The old men’s workings can be seen in the cliffs at the western end of Perranporth beach. The adit level was at 10 fathoms and the lowest workings reached 40 fathoms below the adit. (Courtesy of mindat.org web site)

References:

Ligger Bay: Latitude & Longitude Ref 50.350000, -5.160833

Henwood (1843) noted outcrops of at least one vein, an elvan and two cross-courses in the cliffs near Perranporth, all of which were carrying crystallized quartz. (Courtesy of mindat.org web site)

Reference:

Henwood, W.J. (1843): On the Metalliferous Deposits of Cornwall and Devon. Transactions of the Royal Geological Society of Cornwall 5, 1-386.

Great Wheal Leisure Mine: (No info) Latitude & Longitude Ref 50.3449, -5.15391

North Wheal Leisure Mixed Mine: (No photos or info) Latitude & Longitude Ref 50.3487, -5.14713

Wheal Ramouth Mine: Latitude & Longitude Ref 50.349785, -5.150467

Wheal Ramouth Mine situated in the sand dune area of Perranporth. The only record of output is black tin, reclaimed from the dumps in 1861, 1879 and between 1882 and 1902. (Courtesy of mindat.org web site)

Reference:

The Metalliferous Mining Region of SW England, Dines, Page 448

Perran Wheal Virgin Mine, Callestock: (No photos or info) Latitude & Longitude Ref 50.3006, -5.12991.

Great Callestock Moor Mixed Mine: (No photos) Latitude & Longitude Ref 50.3118, -5.11239.

300 tons lead ore, 190 tons lead mined between 1847-1848. Reported in Geology of Newquay Pg 116.

Great South Wheal Chiverton Mine: (No photos) Latitude & Longitude Ref 50.3094, -5.1024.

Great South Chiverton Mine worked for lead between 1867 and 1873.

It was one of the satellite mines that played on the name of the nearby West Chiverton Mine, which was a large and successful lead mine.

The current remains of the mine comprise an overgrown dump at Engine Shaft, the site of which is identifiable but choked to surface.

The site lies within the grounds of a private residence, which is converted from the former ‘count house’ or mine office.

The site is not accessible for collecting.

It should also be noted that this mine should not be confused with the smaller South Chiverton Mine that was little more than a trial with no recorded production, this latter working lying over 900 metres to the south-east of the Great South Chiverton workings.

Dines in his summing up of Great South Chiverton has made this error and given production figures implied to be for this mine under both of the above names.

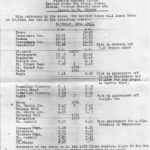

The production figure which given the above should be exclusive to Great South Chiverton are:

1867-73: 160 tons lead ore, 3900 ounces silver, 7 tons zinc ore, 22 tons arsenic and unreported quantities of copper and pyrite.

Chiverton Valley Mine: (No photos) Latitude & Longitude Ref 50.309, -5.11642

Chiverton Valley Mine was a small lead and silver mine, working the southwestward extension of the Chiverton Moor main lode in 1870 and 1871, during which time it produced 85 tons of 77% lead ore, 65 tons of lead & 170 ounces of silver. (Courtesy of mindat.org web site) and Reported in Geology of Newquay Pg 116.

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 502.

Chiverton Moor Mine: (orginally Great Callestock Moor Mine) Latitude & Longitude Ref 50.3118, -5.11239.

Chiverton Moor Mine was a lead and silver mine east of Callestock, first worked in 1847 under the name of Great Callestock Moor Mine and renamed Chiverton Moor Mine when it was restarted in 1866. It was abandoned in 1873.

The workings were chiefly on an EW-trending lode, which changes strike to an almost north-easterly direction in the western part of the sett. It was opened up by three shafts, which are vertical until they pass through the lode and then inclined to follow its footwall down dip. An adit with four air shafts on its back commences near the small stream southeast of Venton Vaise farm and was driven sout-eastwards until it intersected with a minor lode, but it did not connect with any of the workings.

In 1847, Great Callestock Moor Mine produced 110 tons of 60% lead ore. Between 1866 and 1873, Chiverton Moor Mine mined another 2,639 tons of 75% lead ore, 1981 tons lead & 29,715 oz of silver. (Courtesy of mindat.org web site) and Reported in Geology of Newquay Pg 116.

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 502.

Venton Vease Mine (Ward’s Shaft): (No photos) No Grid Ref

A single shaft, called Ward’s Shaft, which is somewhat detached from the Chiverton Moor Mine and was indicated by Spargo as a separate working. Dines lists Ward’s Shaft as belonging to Chiverton Moor Mine and makes no mention of it as having been a separate working, but he also notes, that this shaft tried two lodes which were not worked anywhere else in the sett. According to the mine plans, dated 1869 and 1873, the limited workings on Ward’s Shaft were also not connected with the other workings of Chiverton Moor Mine. (Courtesy of mindat.org web site)

References:

Spargo, T. (1865): The Mines of Cornwall and Devon: Statistics and Observations. Victoria Press (London), 188 pp.

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 502.

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 48SW.

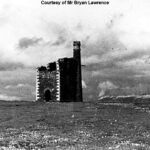

Batters Engine House: West Wheal Chiverton Lead Mine: Latitude & Longitude Ref 50.315833, -5.103056

Between 1866-1872 – 1177 tons of lead ore, 885 tons of lead & 31,062 ounces of Silver was mined. Reported in Geology of Newquay Pg 116.

References:

West Wheal Chiverton Lead Mine: Latitude & Longitude Ref 50.3157, -5.1014

Between 1866-1872 – 1177 tons of lead ore, 885 tons of lead & 31,062 ounces of Silver was mined. Reported in Geology of Newquay Pg 116.

References:

Wheal Wentworth Consols Mine: Ventongimps (No info) No Grid Ref

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 506 (see also corrigenda in the 1994 reprint).

Ventongimps Mixed Mine: (No photos or info) Latitude & Longitude Ref 50.3157, -5.10281

Wheal Chiverton: (Cornubian Mine Marazanvose) (No photos or info) Latitude & Longitude Ref 50.318850, -5.096428

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 505-506 (see also corrigenda in the 1994 reprint).

Mineral Bottom Mine Marazanvose: (No photos) Latitude & Longitude Ref 50.322, -5.10041.

Mineral Bottom Mine was a small trial on a lead lode that is believed to have been the eastward extension of one of the lodes of Wentworth Consols. According to Hamilton Jenkin, the mine was worked around 1868 and was 30 fm deep. The area is now largely obscured by a dense overgrowth. (Courtesy of mindat.org web site)

References:

Dines, H.G. (1994): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, reprint, p. l.

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 48SE.

East Wheal Chiverton Mixed Mine Marazanvose: (No photos or info) Latitude & Longitude Ref 50.3223, -5.09199.

West Cargoll Mixed Mine St Allen: (No photos) Latitude & Longitude Ref 50.361, -5.05795.

West Cargoll Mixed Mine was a lead mine, which was active around 1863. The grid reference marks a large burrow that remains in a field NW of Zelah. (Courtesy of mindat.org web site)

Reference:

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 48SE.

Great Chiverton Consols: (East Wheal Elizabeth) St Allen (No info)

Wheal Frances Mine: (No photos) Latitude & Longitude Ref 50.3279, -5.11625.

Wheal Frances Mine located between Perranwell and Rees. A mine with no records that has an overgrown shaft dump 700 yds. N.W. by W. of Rees (6-in. Com. 48 S.E.).(Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956) The Metalliferous Mining Region of South-West England, Volume 1. H.M. Stationery Office. pg. 497.

Wheal Anna Mine: (No photos) Latitude & Longitude Ref 50.3343, -5.11245.

Wheal Anna Mine with a large sett to the east and north-east of Perranwell (6-in Corn.48 N.E., S.W., S.E.) and adjoining the east side of the New Chiverton sett. The plan (A.M. R 221 B, dated 1838) indicates diagrammatically several lodes coursing about E.-W. The only workings shown are the sites of a few old shafts and an adit with portal opposite the corn mill in Perranwell, extending thence 60 fms. N.E. and then 70 fms. E. by N. with three air shafts. According to Collins (1912, p. 404) the mine produced 558 tons of blende in 1857-60, as well as some pyrite and mispickel; a tin lode is said to have been worked here at an earlier date.

Reference:

Dines, H.G. (1956) The Metalliferous Mining Region of South-West England, Volume 1. H.M. Stationery Office. pg. 497.

Wheal Amelia: (Goonhavern Between Polgoda Road & Engelly Road)(No photos) Latitude & Longitude Ref 50.3363, -5.10556.

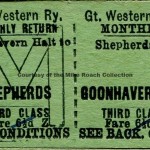

Wheal Amelia Mine was an adit working south-east of the sett of North Chiverton Mine (6-in. Com. 48 N.E., S.E.), with portal on the east side of the stream, 900 yds. N.W. of Rees, and as shown on the Perran Consolidated plan (A.M. R 100 A, dated 1836) follows the valley northwards to a shaft just east of the road, 580 yds. S. by E. of Goonhavem Halt. Thence a drive on a lode underlying 22° S. extends for 50 fms. E.; this is probably the eastward continuation of the North Lode of North Chiverton Mine. It is not known whether any ore was raised.

Reference:

Dines, H.G. (1956) The Metalliferous Mining Region of South-West England, Volume 1. H.M. Stationery Office. pg. 497.

North Wheal Chiverton Mixed Mine: (No photos) Latitude & Longitude Ref 50.335278, -5.109722.

North Wheal Chiverton Mixed Mine was located 1.75 miles E by S of Perranporth. 1-in. geol. 346; 6-in. Com. 48 N.E., S.E.; A.M. R 197 A. Country: killas. The chief or North Lode courses E 20° N and underlies 22° S South Lode, parallel to and 3.5 fms. S of North Lode, has a small amount of development on the east, and No. 1, No. 2 and No. 3 lodes, proved in crosscuts respectively at 44 fms., 47 fms, and 52 fms S of the western workings on North Lode, are not developed.

Mew’s Shaft, 40 yds. E of the road, 800 yds S by W of Goonhavern Halt, is vertical to North Lode just below the 50 fm. level and on the underlie to the 80 fm; Engine or Old Sump Shaft, 107 yds. E.N.E. of Mew’s, is vertical to the 80 fm. Level passing through North Lode at about 40 fms. depth;

Tom’s Shaft, 67 yds E.N.E. of Old Sump, is vertical to the 30 fm. Level and New Engine Shaft, 53 yds. S. of Mew’s, is vertical to the 116 fm. Level passing through the lode below the 100 fm. The plan (dated 1864) shows no adit and the only development above the 50 fm. Level consists of a short 25 fm. Level west from Old Sump Shaft, the 30 fm. Level that connects Old Sump and Tom’s shafts and the 40 fm. Level that extends 18 fms W from Mew’s Shaft. The 50 fm Level, the longest drive, extends for 12 fms E of Old Sump and 55 fms W of Mew’s, a distance of 120 fms. the 60-fm. Level is only 15 fms. E. and W. of Old Sump Shaft; the 70 fm. and 80 fm. levels each connect Mew’s and Old Sump shafts and extend 12 fms. E of the latter and 25 fms. W of’the former, a total of 100 fms.; the 90 fm. Level is driven for 10 fms. W and 60 fms. E of Mew’s Shaft, and the 100 fm. Level for 14 fms. E. there is no drive at the 116 fm. Level at the bottom of New Engine Shaft. The amount of stoping on North Lode is barely 5 per cent of the ground blocked out; the largest stope is 25 fms. long between the 50 fm. and 60 fm. levels, and there are a few small stopes scattered about the other levels, but none below the 80-fm.

Development on South Lode is mainly from crosscuts south from Old Sump Shaft, from which it has been blocked out for about 12 fms. E and 50 fms. W on the 50 fm., 60 fm. and 70 fm. levels; there is also a 10 fm. drive east from a crosscut south from near the eastern end of the 80 fm. Level on North Lode; the amount of stoping is not known.

No. 1, No. 2 and No. 3 lodes are proved in a crosscut 22 fms. S from New Engine Shaft at the 40 fm. Level and in another 27 fms. S at the 50 fm. Level, but the drives on the lodes are all short.

In addition to the above workings, Hick’s Shaft, 263 yds. N.E. by N. of Tom’s shaft, is vertical to 35 fms., and from its bottom a crosscut 10 fms. N cuts a lode on which there are drives 5 fms. E and 2 fms. W.

The only known outputs are for 1864-8 when 100 tons of 75 per cent lead ore, 3,640 oz. of silver, 630 tons of zinc ore and 15 tons of pyrite were produced.

Reference:

Dines, H.G. (1956) The Metalliferous Mining Region of South-West England, Volume 1. H.M. Stationery Office. pg. 497.

Perran Consolidated Mines inc Wheal Albert: Temple, Goonhavern (No photos or info) No Grid Ref.

Perran Consolidated 2.5 miles E. of Perranporth. 1-in. geol. 346; 6-in. Com. 48 N.E.; A.M. R 100 A. Includes Wheal Albert (A.M. R 287 A) or Prince Albert Consols. Country: killas.

The two chief lodes, Anthony’s (on the north) and Mudge’s, are about 17 fms. apart on the west where they course E. 5° N., and about 34 fms. apart on the east where they strike E. 20° S.; both underlie 20° to 30° S. They have been developed for a distance of about 1.270 yds. beneath the alluvial tract east of Goonhavem. The plans of Perran Consolidated (dated 1836) show workings only in the western part of the sett and those of Wheal Albert (dated 1867) only in the east; in a distance of 400 yds. between the two sections there are three old shaft dumps, but no plans of the workings there are known.

Plans of the western section are incomplete and show development only at Adit Level. The shafts on Anthony’s Lode are Adit Shaft, 235 yds. S.E. of the Goonhavem Bible Christian Chapel; Diagonal Shaft, 80 yds. E. by N. of Adit Shaft; Footway Shaft, 56 yds. E. of Diagonal, and three unnamed shafts respectively at 83 yds., 196 yds. and 293 yds. E. of Footway Shaft. Adit Level is shown on the plan in three separate sections, but plan No. 478 at the Duchy of Cornwall Offices, Liskeard, shows it as continuous, following the lode from 25 fms. W. of Adit Shaft to 15 fms. E. of the eastern shaft, a distance of about 260 fms. On Mudge’s Lode are Champion’s Shaft, 140 yds. E. of Adit Shaft of Anthony’s Lode; Mudge’s Shaft, 100 yds. E. of Champion’s, and four unnamed shafts, respectively at 57 yds. E.N.E., 85 yds. E. by N., 158 yds. E. by N., and 207 yds. E. of Mudge’s. New Engine Shaft, 120 yds. E. of Mudge’s, is south of the lode, with a crosscut to it. Adit Level on Mudge’s Lode extends for 28 fms. W. of Champion’s Shaft, and for 107 fms. E. of Mudge’s, the ground between the two shafts not having been opened up. The plan at the Duchy of Cornwall Office shows workings on Mudge’s (Madge’s) Lode on the 13-fm., 20-fm. and 30-fm. levels, for 40 fms. E. and 29 fms. W. of a shaft called Engine Shaft; these cannot be located with certainty.

From the shaft 57 yds. E.N.E. of Mudge’s, a crosscut 207 fms. S. 35° E., with four air shafts, cuts a south-dipping lode at 130 fms. and meets a second at the end; on both there are short drives each way. Drainage adit commences on Anthony’s Lode at Footway Shaft and extends 370 fms. to its portal by the stream, 500 yds. N. by W. of the Bible Christian Chapel; it has seven air shafts and intersects Goonhavem Lode at 133 fms. from Anthony’s. Goonhavem Lode, which underlies steeply south, has been followed for 25 fms. on each side of the drainage adit.

The plans of the eastern section show Engine Shaft, 700 yds. E. of Mudge’s and 500 yds. W. by S. of Lanteague, sunk vertically between the two lodes to the 55-fm. Level (below surface;; Footway Shaft, 90 yds. E. by N. of Engine. Shaft, on the underlie to the 15-fm. Level; Whim Shaft, 50 yds. E. of Footway, on the underlie to the 35-fm.; Eastern Shaft, 100 yds. E. of Whim, on the underlie to the 25-fm. Level, and New Shaft, 100 yds. S.E. of Whim, sunk south of the lode, vertically to 25 fms. with a crosscut from it to the 25-fm. Level on Anthony’s Lode. Crosscuts north from Engine Shaft meet Anthony’s Lode, which is developed for about 130 fms. E. of Engine Shaft on the 15-fm., 25-fm. and 35-fm. levels; the 45-fm. and 55-fm. levels are short. The only drives west are the’15-fm. and 25-fm., which are each 15 fms. long. Sloping extends for 120 fms. E. of Engine Shaft between surface and the 15-fm. Level, and there is some between the 15-fm. and 25-fm. at the eastern end; about 60 per cent of the blocked-out ground has been removed. Mudge’s Lode is only opened up from crosscuts south from Engine Shaft, at the 15-fm. and 35-fm. levels, but the drives on it are short. A crosscut at unstated depth, from Engine Shaft, for 170 fms. S. by W., is connected with Shepherd’s Shaft, but there are no drives from it.

The mine is referred to on Symons’ Map of the Chiverton Mining District, 1869, as Tywarnhayle Mines. Dumps are all of pale grey to black, fissile shale with small fragments of vein quartz. The only record of output is 40 tons of 75 per cent lead ore and 70 oz. of silver in 1852-4. Attempts to reopen the mine about 1861 were apparently fruitless.

Reference:

Dines, H.G. (1956) The Metalliferous Mining Region of South-West England, Volume 1. H.M. Stationery Office. pg. 497.

Wheal Albert Tin Mine: Latitude & Longitude Ref 50.3419,-5.09749.

In 1826 Wheal Albert Tin Mine was only 20 fathoms deep and further sinking was precluded by the limited power of the engine. Under the name of Wheal Albert further trials were made in the 1850’s when a 24″ engine was erected. There was a reworking in the 1860’s on a considerably larger scale. The engine shaft was down to 55 fathoms and had been driven east for 25 fathoms. The lode here was unproductive. The engine shaft was later sunk to 100 fathoms. Good quality blende (zinc) was mined, together with mundic and some lead. (Excerpt from Hamilton Jenkin)

Wheal Albert was worked about 1840 on the western extension of the Old Shepherd’s lodes and the north and south lodes of Wheal Peru. Said to have raised “ large quantities of lead and blende (zinc)” 23 and 35 fathom levels driven a few fathoms only by this company. New company proposing to work in 1861 (see “Progress of Mining,” M.J., 1861). In 1864 was 48 fathoms deep. No adit. 45-inch pumping engine. Seventy people employed in 1870. 40 tons of lead ore, 30 tons of lead & 70 ounces of Silver mined here between 1852 & 1854. Reported in Geology of Newquay Pg 116.

Reference:

Dines, H.G. (1956) The Metalliferous Mining Region of South-West England, Volume 1. H.M. Stationery Office. pg. 497.

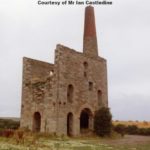

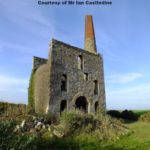

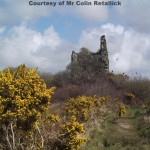

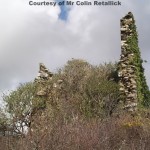

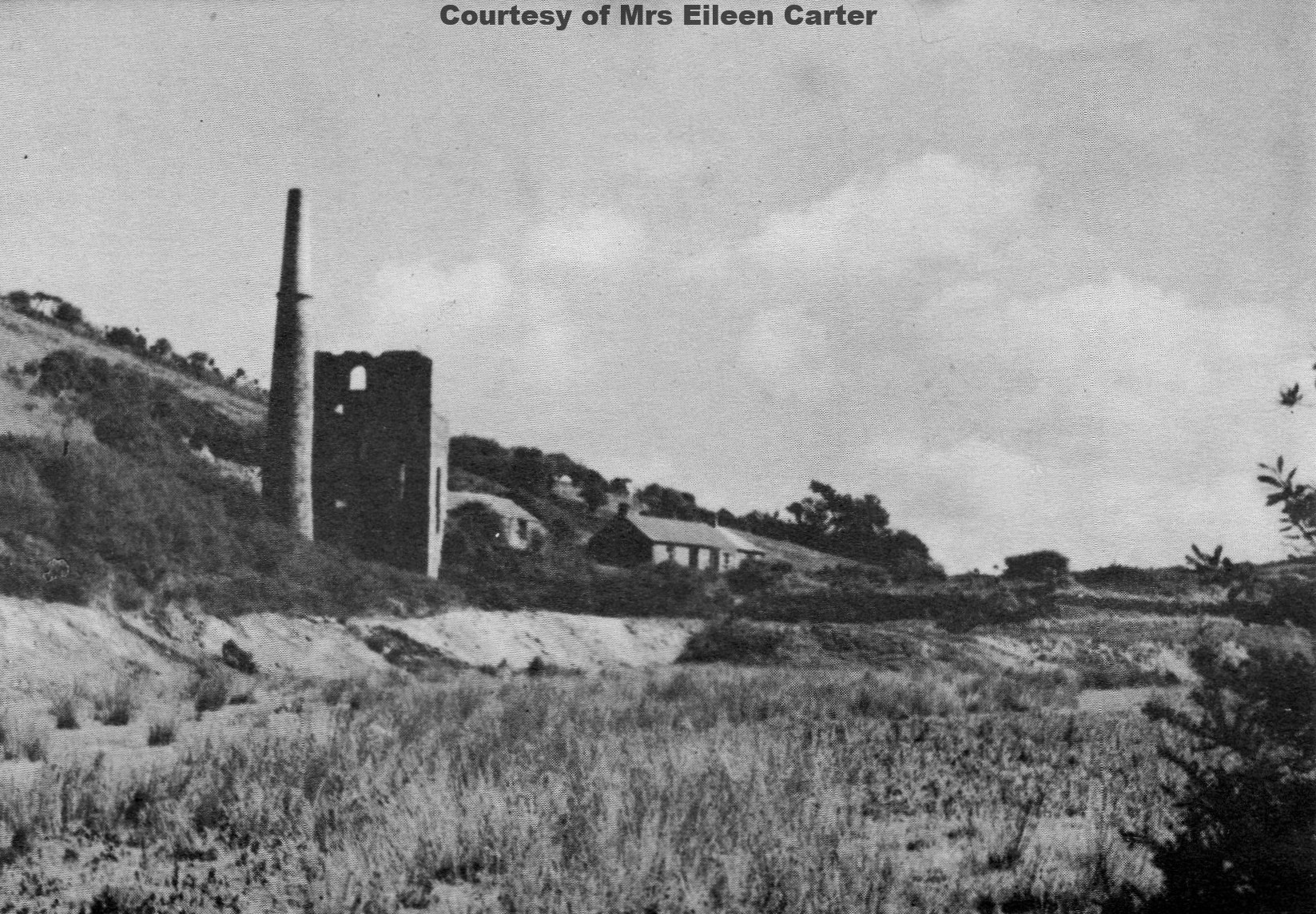

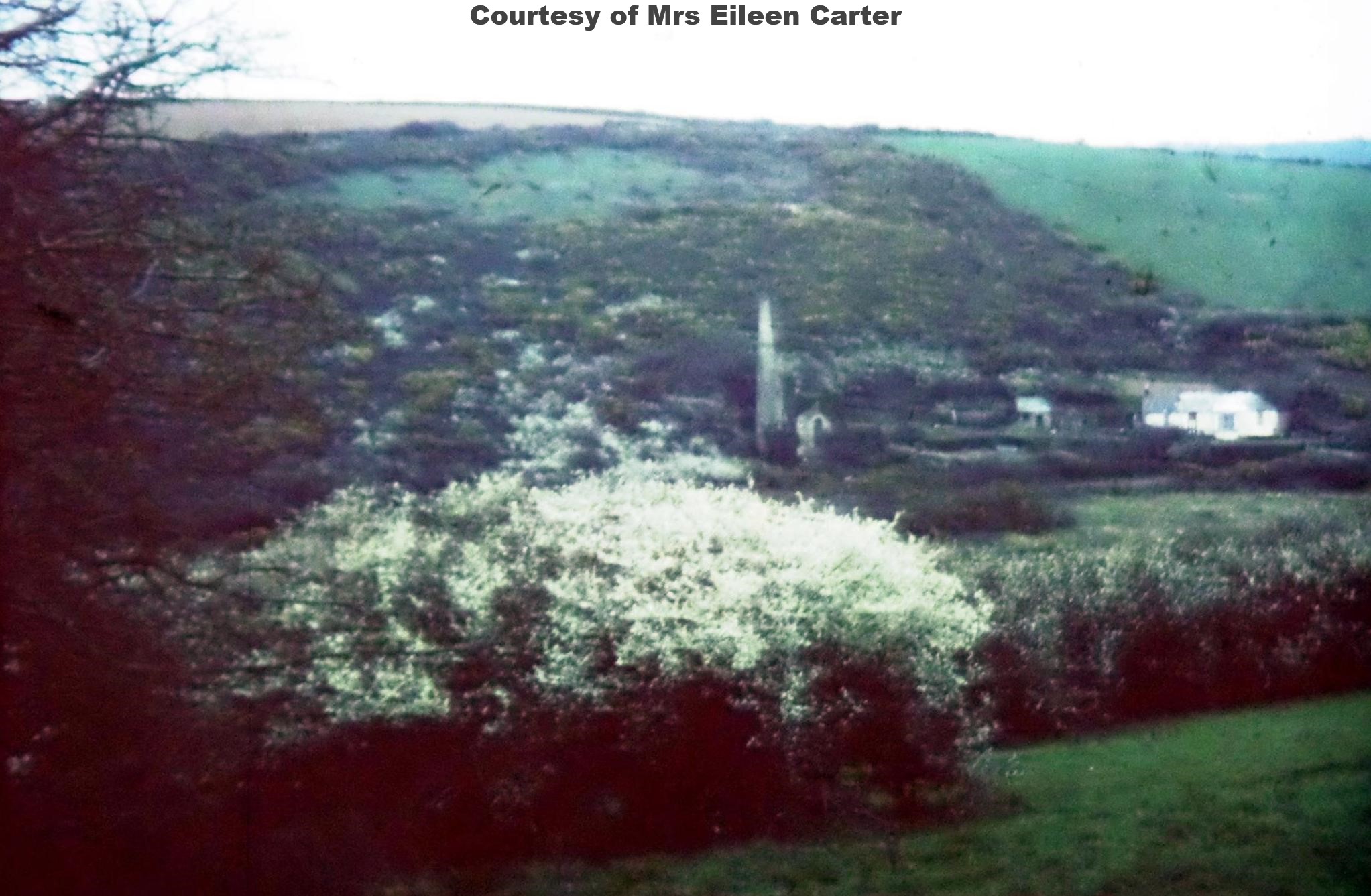

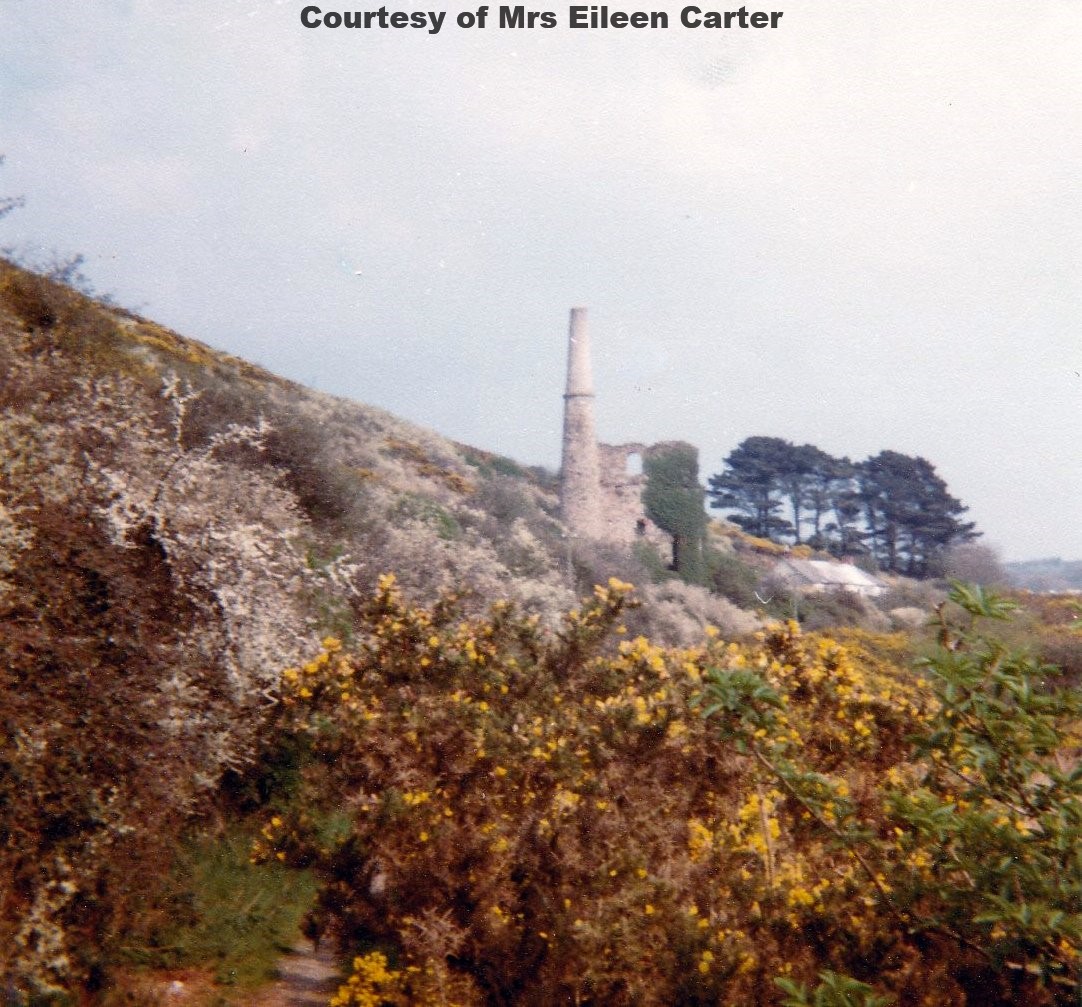

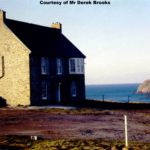

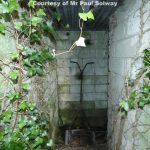

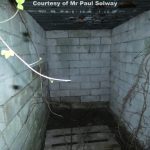

New Wheal Chiverton Mine, Calley Lane, Perranwell: Latitude & Longitude Ref 50.3338, -5.1321.

New Wheal Chiverton Mine was worked between 1864 until 1878. It produced 300 tons of lead ore: 1300 ozs silver: 64 tons zinc: 15 tons pyrite & 25 tons arsenic. There were 4 shafts in the valley and the landowner is Lord Falmouth. The employees numbered 30 men. 1 woman. 4 boys. increasing to 50 employees by 1870, so not a very profitable concern.

Cap’n Grubb lived at New Chiverton farm, so next door really. The powder house was near the stream. It has been told that long ago a man from Perranwell reminisced about dismantling the boiler, it was towed away by the strength of 22 horses.

The engine house is of local stone and a tiny building nearby was a ‘dry’. The count house remains and is in good condition. A sad note, The mine carpenter, William Jewell was killed while at work there in 1878. William Tamblyn, pumpman was also killed. A reminder of what a dangerous way to try and make a living. Courtesy of Mrs Eileen Carter.

Wheal Hope: (No photos or info) Latitude & Longitude Ref 50.350769, -5.113973.

Hendra Croft: (No photos or info) Within 1 km of Wheal Hope. No Grid Ref.

East Wheal Budnick: Hendra Croft (No photos or info) No Grid Ref.

Wheal Rose Mine (Budnick Consols): (No photos or info) No Grid Ref.

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 448-449.

Wheal Budnick Mine: (No photos or info) No Grid Ref.

References:

Reid, C., Scrivenor, J.B., Flett, J.S., Pollard, W., and MacAlister, D.A. (1906): The Geology of the Country near Newquay. HMSO Publications (London), 131 pp.

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 448-449.

Budnick Consols: (originally Wheal Budnick & Wheal Rose) (No photos)

Budnick Consols Mine was formed by amalgamation of two small mines, Wheal Budnick and Wheal Rose, in the area between Rose village and Reen sands. They were started in the early 19th century and initially worked for lead and silver, but later also became copper and tin producers. They were abandoned around 1870, but prospected again in 1926-27 and 1934-35.

The mines jointly worked an ENE-trending main lode (Lead Lode), roughly parallel to an elvan dyke, but interwoven with it in some places, which carried galena, sphalerite and chalcopyrite near the surface, where some cassiterite was present in the wall rocks. At a depth of 44 fm, rich masses of cassiterite-bearing ores accompanied the lode on either side for several fathoms in height, length and width, and at a depth of 74 fm, cassiterite, galena, sphalerite and chalcopyrite ores were mixed. The lead-zinc mineralization thus represents a later infilling of an original tin lode.

During the main period of activity in the 19th century, Lead Lode was exploited on an overall length of 1,200 yards and to a maximum depth of 78 fm. When the workings were prospected for tin in the early 20th century, attempts were made to locate the western extension of the lode, but they remained unsuccessful. In 1934-35, tin showings discovered in an old roadstone quarry in the elvan, just west of the mine workings, were exploited. An old shaft near the quarry edge was opened and irregular strings of quartz with cassiterite were found in the shallow workings. However, the values were erratic and no persistent workable ore bodies were encountered. (Courtesy of mindat.org web site)

412 tons of Lead Ore (1855-1861 & 1897), 299 tons of lead, 10,515 ounces of Silver & 3552 tons of Zinc ore (contains 40% zinc) mined here . Reported in Geology of Newquay Pg 116.

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 448-449.

Wheal Budnick (2nd Dump) SW770546

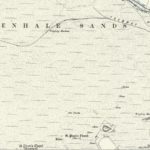

Wheal Reen Mine: (No photos) Latitude & Longitude Ref 50.353757, -5.136668.

Wheal Reen Mine was a small copper mine, working two ENE-trending lodes in the dunes of Reen Sands that were opened up from a series of shafts along their strike. The line of shafts on the more northerly of the two lodes is still easily located in the area between Tollgate and the Perranporth Holiday Park. The workings on the southern lode, about 150 yards apart, are now largely obscured.

There is some contradiction between Dines and Hamilton Jenkin as to the location of this mine. The latter author does not mark Wheal Reen on any of his maps and attributes the workings marked by the grid reference to Wheal Creeg (see separate entry), probably based on Symons’s map of the Chiverton Mining District, dated 1869. Dines, however, points out that this conflicts with the mine plans of Perran Consols, according to which Wheal Creeg was located 400 yards farther north. From 1832 to 1836, the mine produced 100 tons of 5% copper ore. (Courtesy of mindat.org web site)

References:

Reen Sands Mine: (No photos or info) No Grid Ref.

Wheal Vlow Mine: Latitude & Longitude Ref 50.358889, -5.139722

Wheal Vlow Mine formed the central part of the sett of Perran Consols.

The mine produced 120 tons of black tin from 1864 to 1866. The grid reference marks the approximate center point of the workings, now in the middle of a holiday park and largely built over. (Courtesy of mindat.org web site)

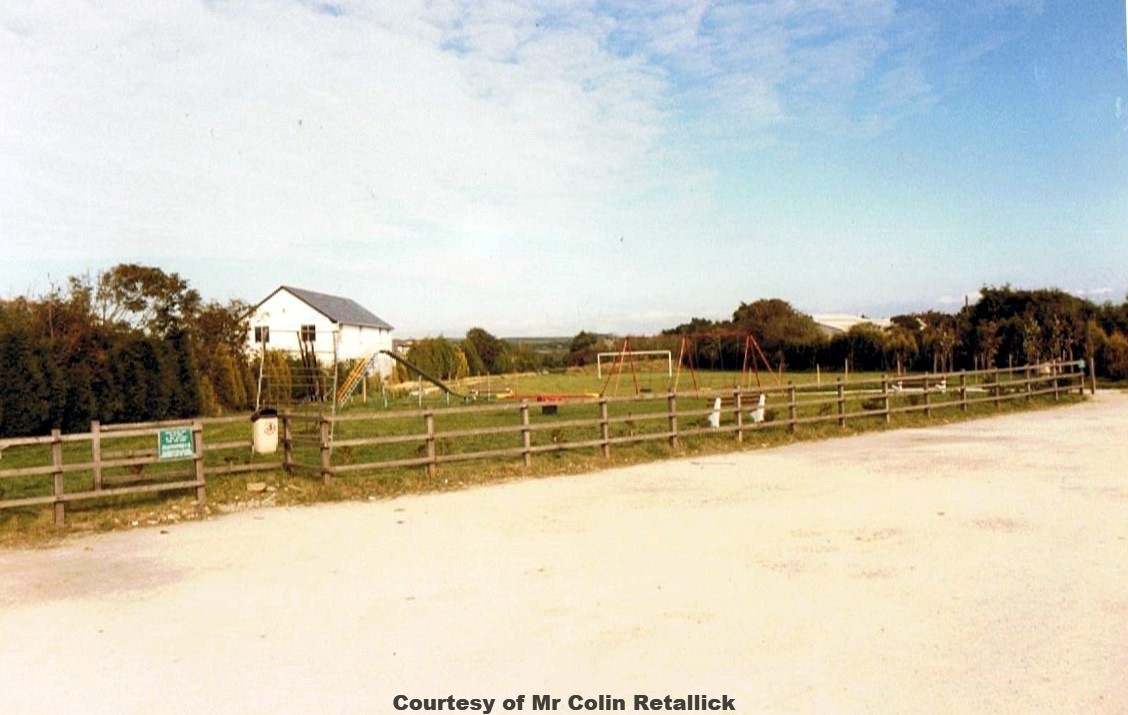

The 1880 OS map shows that Wheal Vlow had 4 shafts, Cowlings, Hallets, Flat Rod & James Shafts along with 2 engine houses. Prior to that in the 1860’s and 70’s there was a 5th shaft – Perry’s. (Courtesy of Mr Colin Retallick)

References:

Wheal Creeg Mine: No Grid Ref:

Wheal Creeg Mine was located just south of Wheal Vlow. It worked two ENE-trending lodes, Wheal Creeg North and South Lodes, about 65 fm apart and trending parallel to the Wheal Vlow Lode. The mine plans show that the northern lode was opened up by crosscuts about 80 fm south from the Wheal Vlow workings. Whether the southern lode was developed or not is not known.

There is some contradiction between Dines and Hamilton Jenkin as to the location of this mine. The latter author places Wheal Creeg about 400 yards farther south, in agreement with Symons’s map of the Chiverton Mining District, dated 1869. These workings however, attributed by Dines to Wheal Reen (see separate entry), show shafts on two lodes that are more than 150 yards apart, which obviously conflicts with the mine plans cited above. It is also unlikely that crosscuts would have been driven from the Wheal Vlow workings for such a distance when there had been shafts on the Wheal Creeg lodes.

Because the extent of workings in the Wheal Creeg section is not known and the area is now largely built over by a holiday park, the mine cannot be precisely located. (Courtesy of mindat.org web site)

Running across Gear Sands parallel with the Tollgate – Mount Road are Wheal Creeg North Lode, Wheal Creeg South Lode and Rowlands Lode.

Wheal Creeg comes from the Kernewek ‘Crug’ meaning barrow. A barrow was recorded on Gear Sands in 1826, but its location is no longer known. (Courtesy of Mr Colin Retallick)

References:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 447-448.

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 48NW.

Perran Consols: (No photos) No Grid Ref:

Perran Consols was a tin mine in the dunes of Gear Sands, formed around 1870 by amalgamation of several small workings. The main lode was Wheal Vlow Lode, which trends ENE and crops out beneath the dunes. It was worked by Wheal Widden in the west and Wheal Vlow in the central part of the sett. Although the area is now largely built over by a holiday park, some traces of the old mine workings are still visible.

From 1869 to 1874, Perran Consols produced 220 tons of black tin. Another 3 tons were raised in 1894 and 1895. In 1927, the mine was reopened, but this did not result in any further production. (Courtesy of mindat.org web site)

In an archaeological report by Cornwall Council that Wheal Vlow and Wheal Creeg were both linked to Rose Mine, Budnick and Wheal Hope in 1835 to form an enterprise under ‘Perran Consolidated’ which employed over 100 people. It went out of business 5 years later. In the 1870’s the enterprise was known as Perran Consols and was made up of Wheal Vlow, Wheal Creeg and Wheal Widden. (Courtesy of Mr Colin Retallick)

References:

Wheal Widden Mine: (No photos) No Grid Ref.

Wheal Widden Mine was a small mine in the western part of the sett. It worked the Wheal Vlow Lode from three shafts at a distance of about 300 yards from the coast. The extent of the workings is not known. (Courtesy of mindat.org web site)

Reference:

Wheal Mary: No Grid Ref:

Wheal Mary was a small mine in the dunes of Penhale Sands, about half a mile south of the Gravel Hill Mine. The portal of the adit is located at the foot of the cliffs immediately west of the workings. According to Dines, it worked an ENE-trending lode for tin and copper. Hamilton Jenkin, however, states that it worked a NS-trending lode for copper and lead. There are no records of output. (Courtesy of mindat.org web site)

Taking a walk across Perran beach, one traverses the ancient tin mines of Droskyn to the Tudor lead mines of Ligger. The first such examples of the latter to be met with when travelling north is Wheal Mary.

This mine is recorded prominently in the district throughout the mid 19th century on mapping, however no detailed underground plans exist for the mine itself. Two lodes (themselves the continuation of the Penhale/Golden Lodes) were worked for lead, and a crosscourse – which is visible as a rocky outcrop rising above the sand dunes 1/2 way along the beach – from which an adit was driven from adjacent high tide level. The remains solely exist in the form of a few obliterated shafts in the middle of the towans and the odd spoil heap.

(Courtesy of Ben Sum, Helston (12/5/18)

References:

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 39SW.

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 447.

Halwyn Pit: (Halwyn Mine) (No photos)

Halwyn Pit was a small opencast working on the Perran Iron Lode. Two open shafts WNW of the pit (SW772567) also belong to the sett. There are no mine plans, nor records of output. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 442.

Mount Mine: Latitude & Longitude Ref 50.365848, -5.121993

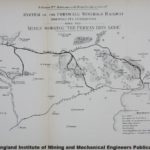

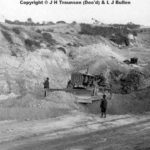

Mount Mine was an iron mine on the Perran Iron Lode, originally worked opencast from two pits, a small western one and a large eastern one, about 70 yards apart. The eastern pit was 200 ft long, up to 80 ft wide and 100 ft deep. The oxidation of the siderite stopped at about 50 ft below surface and the workings at the bottom of the pit, which were in two large chambers, exposed massive grey siderite ore with scattered specks of sulphides.

An adit, wide enough to take normal-gauge railway wagons, was driven from 300 yards NNE of the eastern pit to open up the lode at greater depth. It passed 40 ft below the pit, to which it was connected by an ore-pass winze. A mine plan shows that drives were carried out from the tunnel below the pit 100 ft east and 150 ft west at two levels. Several crosscuts from each of the drives cross the position of the lode, but there is no stoping shown, indicating, that the rich orebodies which were certainly expected were not found.

There also are two old shafts NE and NNE of the pit, which are believed to be on the southern extension of Trebisken Lode. According to the plans, the shafts were connected to the adit, but it is not known whether the lode was exploited here. However, some lead and silver ores were sold when the mine was operated as Mount and Trebisken Mine.

Mount Mine was reopened in 1916 without success and during the Second World war (1939-1945), was investigated as a source of iron ore. An inclined shaft was sunk just east of the eastern pit and followed the footwall of the lode. Drives were carried out on both sides to prove the lode, but the values were rather patchy and wartime production remained small. The grid reference marks the site of Engine Shaft. The chimney of the engine house still stands in the field south of the eastern pit, which is now backfilled and overgrown.

From 1858 to 1877, the mine produced 45,826 tons of brown iron ore, 5.5 tons of lead ore, 10 tons of silver ore and some native silver under the name Trebisken and Mount. As Mount Mine, it produced 4,262 tons of iron ore in 1871, 1873, 1880, 1905 and 1907, and 11 tons of lead ore in 1854. As Perran Iron Mine, it returned 164 tons of brown iron ore in 1866 and, for the New Perran Iron Company, another 2,728 tons of iron ore and 49 tons of manganese ore were recorded in 1878. (Courtesy of mindat.org web site)

References:

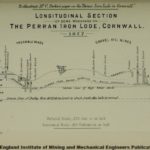

At this mine two or three openings have been made, from which many thousands of tons of iron ore have been raised, nearly the whole of which has been brown hematite, as the workings have not been deep enough yet to reach the white spathose. “see Longitudinal Section of some Workings on The Perran Iron Lode – 1877 below”

There is nothing to notice here except that the openings have proved the continuation of the deposit or lode. Analyses of ore from this mine, by Dr. Percy, give the following results:- Metallic iron- 52.91 % & Metallic manganese- 2.36 %

(Courtesy of “On the Perran Iron Lode in Cornwall & The Mines in the District by Charles Parkin)

South Mount Mine: (Crows-an-Carne Mine) (No photos) No Grid Ref:

South Mount Mine was a small open cut in a pipe-like body of iron-bearing carbonates (“spathic ore”). Analysis of a sample collected in 1941 shows a rather low iron content, but much calcium and magnesium; the material thus has to be considered as an iron-bearing dolomite. The pit was located just east of the road leading to Perranporth, but is now completely backfilled. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 443.

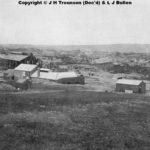

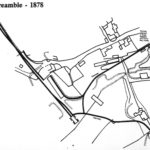

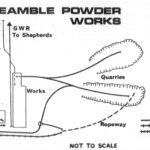

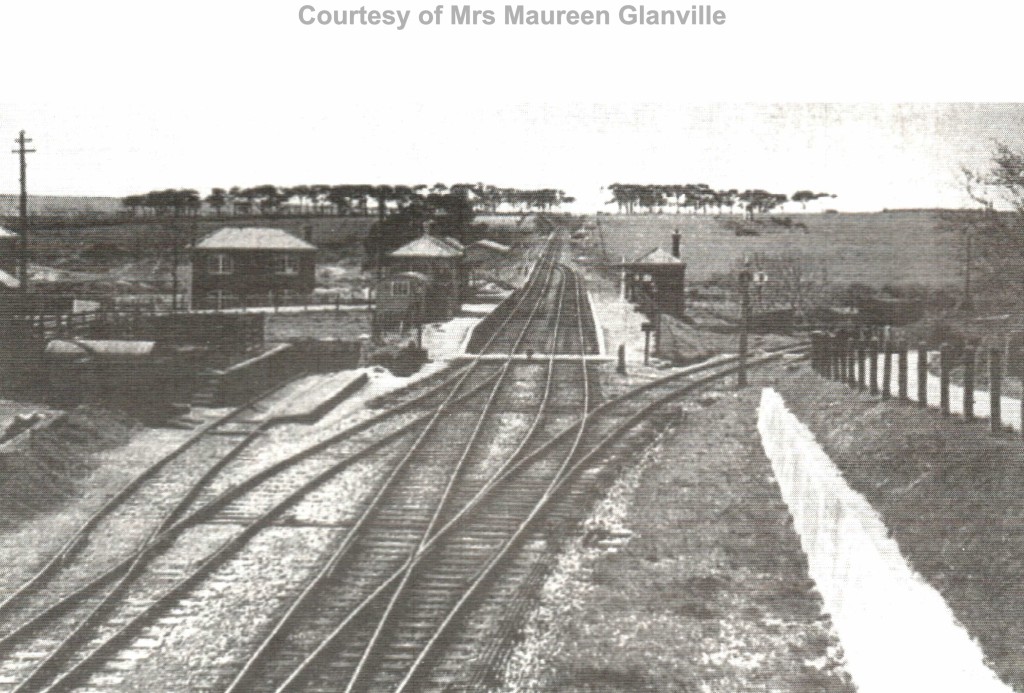

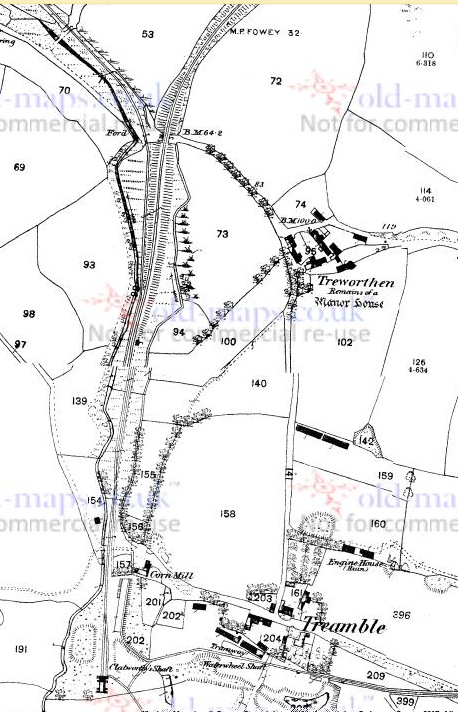

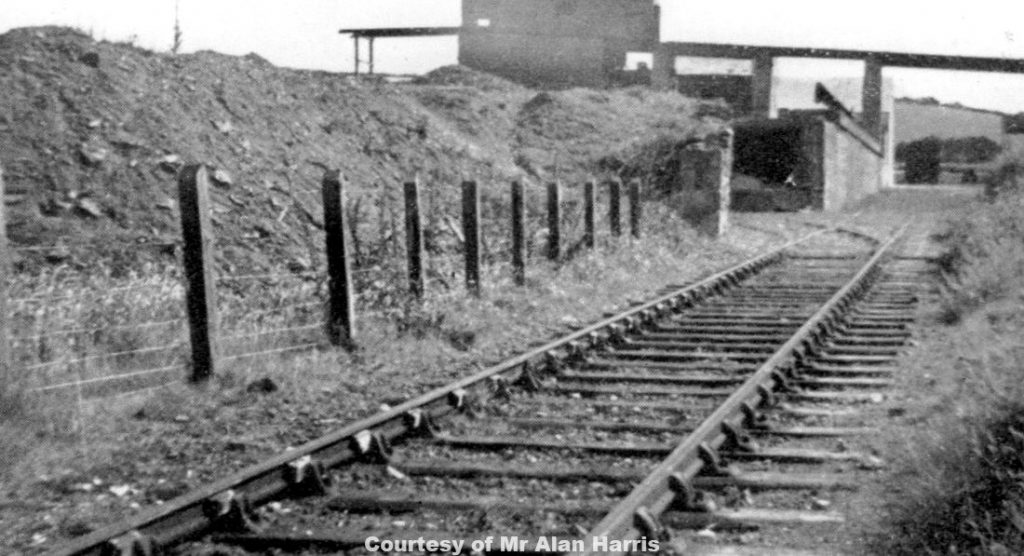

Treamble Works & Mine: Latitude & Longitude Ref 50.361389, -5.113056

Treamble Mine was an iron mine on the Perran Iron Lode, started in the middle of the 19th century and worked intermittently until the second world war. The lode, which passed about 30 yards south of Treamble farm, was originally worked from two open cuts, located SW and SE of the farm, respectively. When the western pit was excavated, a NS-trending lead lode was exposed which is believed to represent the southern extension of Trebellan lode that also was worked a little further north by North Retallack Mine. The lode is said to have intersected with the Perran Iron Lode, close to which it carried native silver and silver ores.

The pits opened up the lode on an overall length of 235 yards. The extent of workings in the western pit is not exactly known, because it was backfilled early. The eastern pit, also known as Garden quarry, was 60 ft deep and up to 120 ft wide. Later on, shallow shafts were sunk along the strike of the lode, but not much further underground development was carried out. Dines notes that the very limited amount of stoping shown on the mine plans, and the exposures in the eastern pit do not justify the reports by contemporary authors about the amount and quality of the ores raised.

The early period of activity ended around 1892 and the mine lay idle until 1937, when it was taken over by Lloyd’s Perran Iron Company. A new pit, 250 yards long and 150 yards wide, was excavated to a depth of about 20 ft in the eastern part of the sett. However, no continuous ore bodies were encountered and the lode, which was expected to be about 40 ft wide, was not thicker than 14 ft. In 1940, after about 4,000 tons of ore had been raised, the workings were abandoned and the mine was taken over by the Home Ores Department, who did some further development and continued working it until 1943.

The area has now been converted into a caravan park. The pits are backfilled and there are no traces of the mine workings left. The grid reference marks the site where the eastern pit was located.

From 1859 to 1892, the mine produced 15,300 tons of brown iron ore, 958 tons of mixed brown iron and spathic ore, 32 tons of 75% lead ore, 7 tons of 40% zinc ore and 130 oz of silver. From 1937 to 1940, 4,000 tons of iron ore were raised, and another 15,000 tons of ore are recorded for the last period of activity between 1940 and 1943. In addition, up to 500 tons per year of fullers earth were produced from decomposed killas. (Courtesy of mindat.org web site)

References:

The lode has been worked away to a considerable extent here by means of an open quarry (H), Plate No. XVI. “see Longitudinal Section of some Workings on The Perran Iron Lode – 1877 below” , or cutting about ten fathoms deep. The brown hematite cropping out to the surface, and the white spathose plainly visible in the bottom.

“I” is a shaft worked by a water-wheel in the valley below at the bottom of which a lead lode was cut, from which a quantity of lead ore, highly productive in silver, was raised.

“J” is “Parkin’s” shaft, at which a sixty-inch pumping engine is erected. The shaft is 20 fathoms deep.

“K” is “Berriman’s” shaft and workings, where most of the ore sold from this mine was raised, and where the lode is larger than at any other point which has been opened tip. A kiln has been erected here for roasting the ore, but it is constructed in such a manner that it is very doubtful of its being equal to the work for which it is intended. (Courtesy of “On the Perran Iron Lode in Cornwall & The Mines in the District by Charles Parkin)

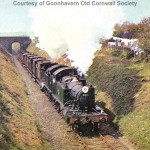

Treamble Mine, 1920s. Two miles NE of Perranporth. Although situated in an area where principally mined iron ore, a further product at Treamble was the soft talcky substance calk Fullers Earth. Some 500 tons a year was sold for such diverse uses as refining of vegetable for a filler for paint, rubber and bituminous products.

North Retallack Mine: (No photos) Latitude & Longitude Ref : 50.363333, -5.111944

North Retallack Mine worked several NS-trending lodes in the area immediately north of the Treamble mine. One of the lodes was the southern extension of Trebellan lode, and it is also believed, that it was this lode that was exposed in the western pit of the Treamble Mine.

The mine formed part of the Great Retallack sett. It produced 5 tons of lead ore in 1869. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 444-445.

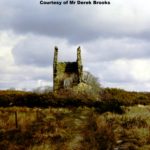

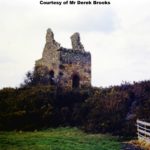

Great Retallack Mine: Latitude & Longitude Ref: 50.359722, -5.106111

Great Retallack Mine worked the Perran Iron Lode for about 300 yards east of the Treamble Mine. The grid reference marks the site of Engine Shaft. Hamilton Jenkin notes that the engine house still standing there in 1953 was wantonly destroyed in 1956. Today, no trace of the workings is left.

Between 1858 and 1880, the mine produced 10,826 tons of iron ore, 11,639 tons of zinc ore, 198 tons of 75% lead ore and 600 oz of silver. (Courtesy of mindat.org web site)

References:

The writer has not had the opportunity of personally inspecting this mine, but the owner of the royalty, Francis Retallack, Esq., has been kind enough to supply the following information, which goes to show that it is a very valuable mine. It has been worked for many years for iron, silver lead, and blende, more especially for the latter mineral. Upwards of £2,000 has been paid in royalty dues, which for so small a plot of ground is a considerable sum. The quantity of lead ore sold was very small, but it contained so much silver that it made a very high price, one parcel, it is understood, bringing the unusually high figure of nearly £300 per ton. The pumping engine at the adjoining mine (Duchy Peru) drains the whole of this sett, which at present is being worked for blende only. (Courtesy of “On the Perran Iron Lode in Cornwall & The Mines in the District by Charles Parkin)

Duchy Peru Mine: (No photos) No Grid Ref.

Duchy Peru Mine was the largest and deepest mine on the whole Perran Iron Lode. It lies about 400 yards southwest of Rejerrah. Like many other mines on the lode it was formerly worked as an open work. It worked the lode from a number of shafts: Roebuck’s, Vallance’s, Carter’s New, Carter’s Old, Tennant’s and Old Engine (Old Sump) Shaft.

Between 1858 and 1860, Duchy Peru produced: 21,400 tons of Haematite, 11,000 tons of mixed haematite/spathic ore, 760 tons of pyrite, 180 tons of ochre and umber, 20,000 tons of zinc ore (ranging from 20% to 47% metal, and 3 tons of 34% lead ore. In 1860 it raised 185 tons of 3.5% copper ore and 185 tons of silver-copper. Courtesy of Mr Kenneth Rainbow.

The most extensive mine developed on the Perran Iron Lode. The lode was first worked by open casts; then by shafts sunk to a depth of 145 mts at Roebucks shaft. In would appear from Dines (1956) that the ore shoots were confined between NNW transverse planes (?faults). The iron lode is intersected by a N-S lead lode, which has some development on it. The mine is known to have been active at times between 1828-86. The decomposition of pyrite in the mine is said to have been a problem. Due to the high temperatures and bad air it created.

Recorded output between 1858-86: 3 tons of lead ore, 1 ton lead, 22,7151 tons of zinc ore, 34,000 tons of iron ore, 185 tons of Silver (1860) 1,041 tons of pyrite, 180 tons of ochre & 185 tons of copper ore, 26,295 tons of Haematite and over 11, 000 of Spathic ore mixed with hydrated Haematite.

In 1884 the ore being raised contained 42% iron. The Zinc ore contained from 20% – 47% of Zinc and in the best years averaged 45%. (Courtesy of mindat.org web site) and Reported in Geology of Newquay Pg 116.

The most extensive mine developed on the Perran Iron Lode. The lode was first worked by opencasts; then by shafts sunk to a depth of 145 mts at Roebucks shaft. In would appear from Dines (1956) that the ore shoots were confined between NNW transverse planes (faults). The iron lode is intersected by a N-S lead lode, which has some development on it. The mine is known to have been active at times between 1828-86. The decomposition of pyrite in the mine is said to have been a problem. Due to the high temperatures and bad air it created.

Recorded output:

34000 tons of iron ore

760 tons of pyrite

180 tons of ochre

20000 tons of zinc ore

185 tons of copper ore

3 tons of lead ore

References:

Smyth, W. (1882): The Duchy Peru Lode, Perranzabuloe. Transactions of the Royal Geological Society of Cornwall 10, 120-130.

Reid, C., Scrivenor, J.B., Flett, J.S., Pollard, W., and MacAlister, D.A. (1906): The Geology of the Country near Newquay. HMSO Publications (London), 131 pp.

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 445-446.

Not only have many thousands of tons of iron ore been raised from this mine, but also quantities of copper, sulphur, mundic, and blende.

“L” is “Carter’s” shaft (Plate No. XVI.) “see Longitudinal Section of some Workings on The Perran Iron Lode – 1877 below” sunk down to the forty-fathom level, the brown hematite (of “cellular” character) from this point was unexceptionally good and free from all impurities; stones of white spathose were frequently met with towards the bottom of this shaft, enveloped in a shell of cellular brown ore of about an inch in thickness.

“M” is “Roebuck’s” shaft, which is the most important one of all which have been sunk on the lode, proving, as it does, the existence of while spathose ore to a depth of nearly seventy fathoms, and thirty fathoms at least below the datum line of high-water mark. A sixty-inch cylinder pumping engine is erected here, which draws about 500 gallons of water per minute. This engine is draining the water from the next mine (Deer Park), a distance of about one and a half miles.

“N” is “Vallance’s shaft sunk for winding purposes, and is fifty fathoms deep. An inclined tramway connects this mine with the Treamable Mines and the Cornwall Minerals Railway. (Courtesy of “On the Perran Iron Lode in Cornwall & The Mines in the District by Charles Parkin)

Deer Park Mine: (No Photos) Latitude & Longitude Ref: 50.357917, -5.082095

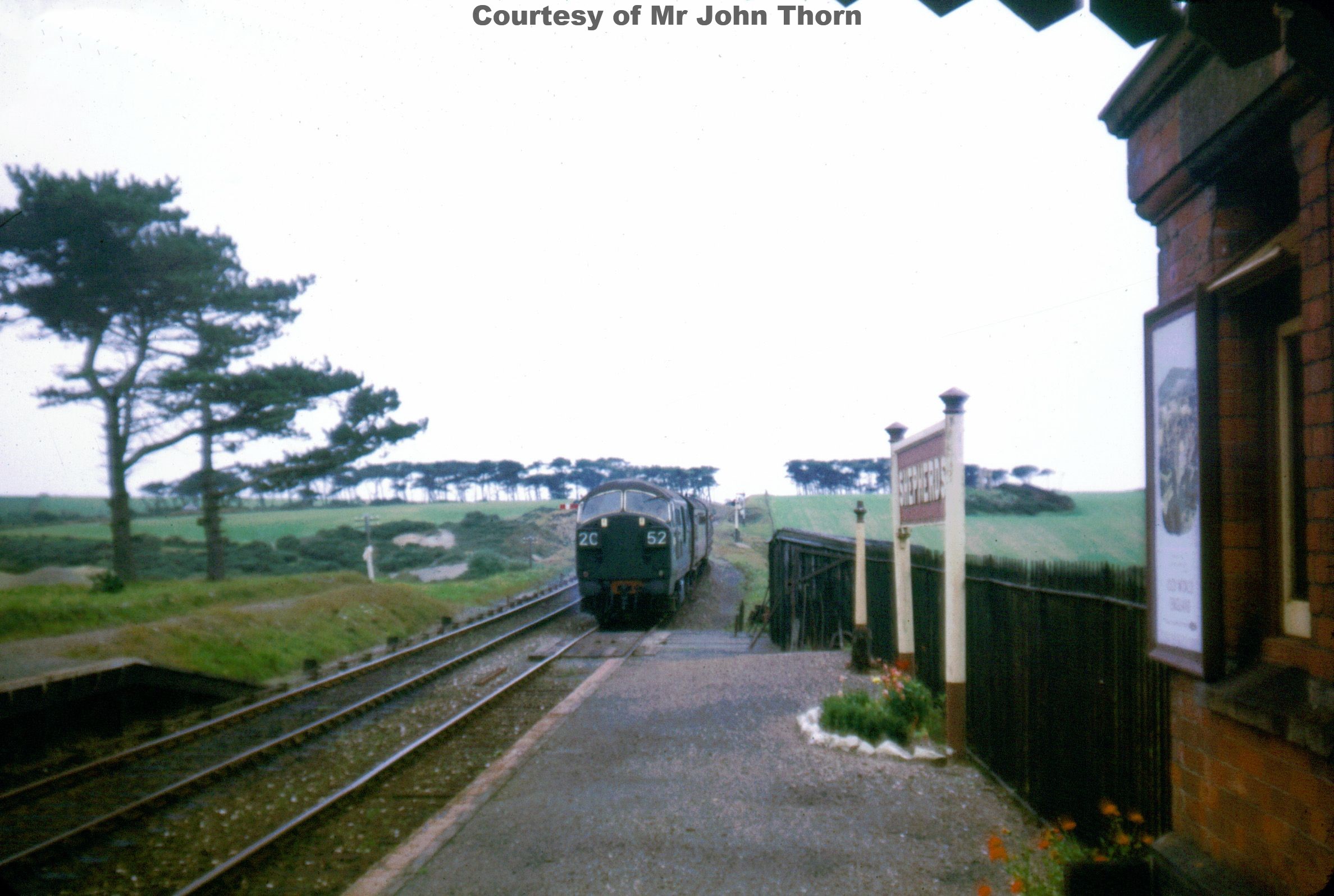

Deer Park Mine was an unsuccessful venture, working the furthest eastern extensions of the Great Perran Iron Lode for iron from 1875 to 1879, but is known to have been at work long before this date. In about 1814 whiel an adit level being driven towards the iron lode it intersected a lead lode (Dines says there were 3 or 4 north-south lead lodes). A few dumps and pits are left in the fields near the abandoned Shepherds branch railway line. The iron lode has been traced for a further 1.5 kms east, but there are no recorded workings.

Recorded output: 267 tons of iron ore; 3 tons of lead ore & 10 tons of zinc ore. (Courtesy of mindat.org web site)

References:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 446-447.

Atkinson, B. (1994): Mining Sites in Cornwall, Vol. 2, Dyllansow Truran (Truro), 51 pp.

This is the most easterly point at which the Perran iron lode has been opened, and is in close proximity to the celebrated East Wheal Rose and Shepherd’s Lead Mines, the former having divided about £287,000 in twelve years, and the latter about £80,000 in sixteen years. See Plates XVI. and XVII. “see Longitudinal Section of some Workings on The Perran Iron Lode – 1877 below”

In the Deer Park sett there are three lead lodes, and the iron lode discovered, and the writer will now give detailed particulars of the workings, which he thinks go to confirm the theory that this large deposit of iron, is merely the “back,” or gossan, of lead and copper lodes respectively.

No.1 lead lode (Plate No. XVII.) “see Longitudinal Section of some Workings on The Perran Iron Lode – 1877 below” is an east and west one, which was discovered by means of an adit taken up from the “Whipsey” Pit, about fifty fathoms west of the “Old Engine” shaft, and worked upon about fifty years ago. This adit was driven on the course of the lode, producing iron pyrites and lead ore. The result induced the company to put up steam power at the “Old Engine” shaft, which was sunk twenty- five fathoms below the adit, and levels were driven east and west on the lode eleven fathoms below it, which yielded about one ton of lead ore per fathom. From the bottom of the “Old Engine” shaft a quantity of white spathose iron was raised, but at this time, in the year 1882, there being no demand for Cornish iron ore, and the price for lead being only about £8 per ton, the mine was stopped. The iron ore has, however, been picked out of the burrows lately and sold. This lode (lead) is about 2 feet 6 inches wide, mid is composed of floogen, decomposed elvan, spar, and small lead ore; it has been also cut about 100 fathoms east of the u Old Engine” shaft, and galena taken from it at this point, within ten fathoms from the surface, yielded about 70 per cent, of lead and upwards of 15 ounces of silver per ton.

At the “Whipsey” pit the lead lode comes in contact with the iron lode, and the latter is so impregnated with lead ore that it is found profitable to stamp it by hard labour for the lead alone. If it were probable that this lead-bearing iron ore was to be found in any bulk in depth, proper stamps would he erected to crush it; but the writer is of opinion that the iron lode will die out in depth, and give place to the lead ore.

No.2 lead lode, also an east and west one, was cut near “Barton’s shaft in the year 1875, and since that time several parcels of lead ore has been raised, yielding about 22 ounces of silver per ton, and it sold for about £18 per ton. These parcels were got within four fathoms of the surface.

“Barton’s” shaft has now been sunk down to the eleven-fathom level “old workings” where the operations go to show that although large quantities of lead ore have been stored away, yet nothing has been done on the iron lode which is impregnated with lead here again. By sinking this shaft ten fathoms deeper the lead lode will be intersected in the shaft.

No.3 lode is about 18 inches wide, producing stones of lead ore, which were analysed by Captain Champion, and found to contain 30 ounces of silver per ton and 80 per cent, of lead.

From the iron lode about 10,000 tons of iron ore have been raised by the late company who worked the mine, all of which has been quarried from openings of about three to four fathoms deep, but hundreds of tons have been of this quantity have been full of lead ore; in some cases stones of iron ore have contained so much as 40 per cent, of lead, and the percentage of lead in one cargo of iron sent away was 20 per cent. But taking the iron lode at the depths to which it has been proved to be productive at the various mines, it must yield a very large quantity of ore; and if in depth it should give place to either lead or copper, the latter deposits will no doubt be unusually rich ones from the fact of having such a rich “gossan” overlying them. (Courtesy of “On the Perran Iron Lode in Cornwall & The Mines in the District by Charles Parkin)

Old Shepherds Mine: (No photos) Latitude & Longitude Ref: 50.346389, -5.069444

Old Shepherds Mine was 1.5 miles S.S.W. of Newlyn East. 1-in. geol. 347 ; 6-in. Com. 48 N.E.; A.M. R 77 A. Country: killas.

The only plan of this lead mine is really a longitudinal section and the shafts cannot be located with certainty. From their alignment on the Ordnance map the lode probably courses about N.E., but neither the underlie nor whether the shafts are vertical or inclined can be determined. Engine Shaft may be that surrounded by a small dump nearest the centre of a field 650 yds. N.W. of Shepherds village.

Engine Shaft is down to 120 fms. below adit (10 fms.); Flarvey’s Engine Shaft and Teague’s Shaft, close together about 80 yds. S.W. of Engine Shaft, are each sunk to the 100-fm. Level and Footway and Boundy’s shafts, respectively 105 yds. and 200 yds. S.W. of Engine Shaft both reach the 34-fm. Level; East Shaft, 150 yds. N.E. of Engine Shaft, is to the 92-fm. Level. The ground is blocked out by levels at approximately 10-fm. intervals for about 100 fms. N.E. and 100 fms. S.W. of Engine Shaft, down to the 92-fm. Level; the 100-fm. Level is a little shorter and the 110-fm. extends just over 30 fms. each way; there is no drive at 120 fms. below adit. Adit Level is shown on the plan as continuing 60 fms. N.E. and 100 fms. S.W. beyond the limits of the lower levels. There are several adit shafts and adit portal is probably near the stream a quarter of a mile S. of Deerpark Mine.

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, pp. 498

Peru Mine: (No photos) Latitude & Longitude Ref: 50.367198, -5.105203

Peru Mine a small lead mine, located on the south side of the valley SE of Trelaske farm. It worked a NS-trending lode and two EW-trending lodes, about 100 yards apart, that cross the former. Several shafts and some overgrown dumps are remaining in the woodland near the river. Not to be confused with the Duchy Peru Mine. (Courtesy of mindat.org web site)

Reference:

Dines, H.G. (1956) The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 440.

Wheal Mexico Mine: Latitude & Longitude Ref: 50.368611, -5.112222

Wheal Mexico Mine a small lead mine, working a NS-trending lode (Trebellan lode) in the valley south of Trebellan farm. It was already worked before 1584, presumably for silver. Around 1785, rich silver ores were discovered and the mine was restarted under the name Wheal Mexico. Although the deposit was not extensive, it yielded £2,000 pounds worth of ore (Carne, 1818). The later workings were on both sides of the river, straddling the border between the parishes of Cubert and Perranzabuloe.

According to Hamilton Jenkin, the Tithe map of Perranzabuloe, dated 1843, shows Wheal Mexico immediately north of Treworthen farm, on the south side of the river (in Perranzabuloe parish). These workings are probably identical with the Treworthy Mine described by the German Ulrich Frosse in 1584. An earlier working by the German Burkhard Kranich is recorded at the time of Queen Mary, between 1553 and 1558. Philip Rashleigh visited the mine and obtained a specimen of native silver.

The southern extension of the lode runs through the sett of North Retallack Mine and enters that of Treamble Mine (see separate entry), where it is said to intersect with the Perran Iron lode. About 20 fm north of the presumed intersection, it carried silver ores and native silver in addition to argentiferous galena. (Courtesy of mindat.org web site)

References:

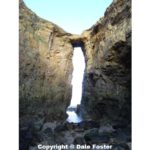

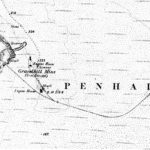

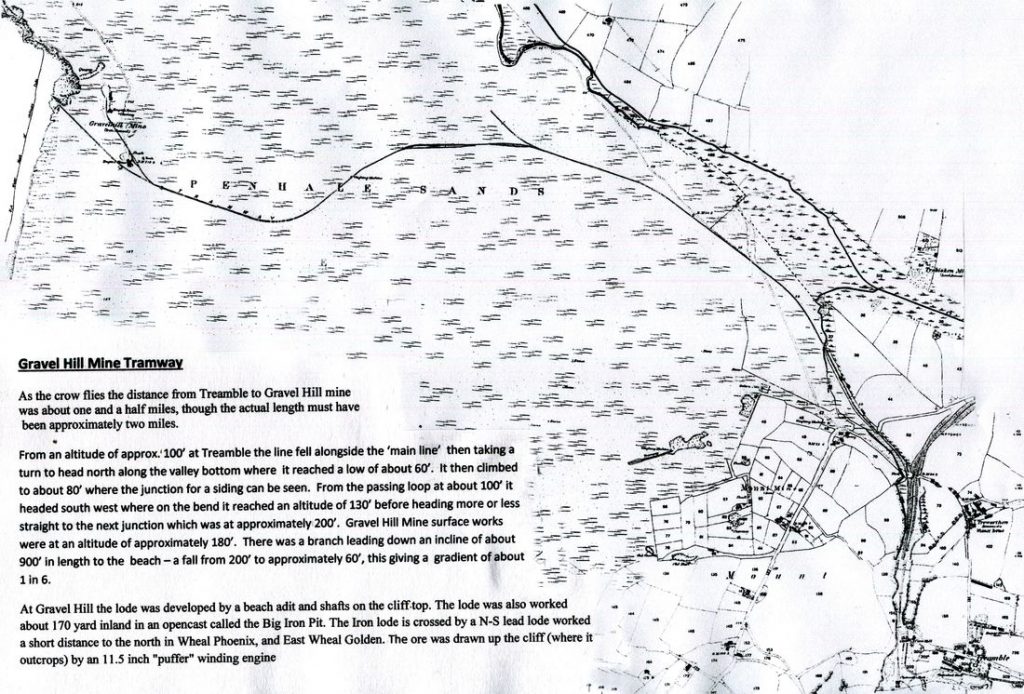

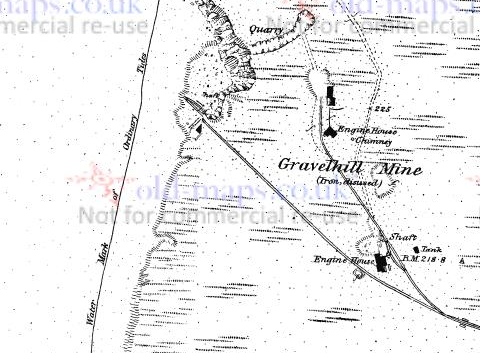

Gravel Hill Mine & Quarry – The Big Iron Pit: Latitude & Longitude Ref: 50.374167, -5.145000

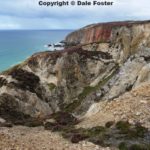

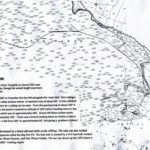

Gravel Hill Mine (earlier known as Penhale Iron Mine and Cliff Iron Mine) worked the western end of the Perran Iron Lode. Where the lode crops out in the cliff, it consists of two branches that are separated by a course of killas. Both branches were worked from the cliff face, and the stopes still stand as large caverns. About 170 yards SE of the cliff workings is a small but deep opencast called the Big Iron Pit. Another excavation just north of the caverns is from an old quarry in an elvan dyke and not related to the mine workings.

Underground development was carried out from an adit at beach level, which follows the north branch of the lode, and from shafts near the cliff edge. The base of the oxidized zone is about at adit level. Below this, the lode is reported to narrow and to consist mainly of blue fluccan (clay) with fragments of sulphides. About midway between the cliff and the Big Iron Pit, the lode is crossed by a NS-trending lode, which is believed to represent the southern extension of the lode worked at the Phoenix Mine.

The mine is known to have been active before 1728, but output figures are only available for the later workings. Between 1874 and 1882, it produced 7,400 tons of brown iron ore grading at 47% Fe, 10,379 tons of mixed limonite and spathic ores, and 30 tons of 40% zinc ore. Another 165 tons of brown iron ore recorded in 1866 under the name Perran Bay may refer to the cliff workings. When the mine was reopened around 1916 (Cantrill et al., 1919), it apparently did not produce any ores. (Courtesy of mindat.org web site)

References:

Nearly the whole of the surface of this sett or royalty is covered with sandhills. A reference to the geological map of the district will show it marked “blown sands,” which consist of the detritus of sea shells. Analysis shows them to contain from 80 to 85 per cent, of carbonate of lime and some phosphates. These sands are so light that they are blown for miles inland, and a Church, “St. Piran’s,” which was built in this district, was enveloped in sand to such an extent that about the year 1800 it was found necessary to pull it down and build it further inland.

The workings consist of an adit “C” on Plate No. XVI., see Longitudinal Section of some Workings on The Perran Iron Lode – 1877 below”, which has been driven in from the base of the cliff (a few feet above high-water mark) by the side of the lode which intersects at about 60 fathoms in from the cliff. The bearings differ at this point from the general bearings of the lode, which has, together with other indications, led many to believe that this is either a distinct lode, or a branch from the main one. “D” is a shaft sunk down to this level, going through the brown hematite overlie, into a mixture of that ore and white spathose. “E” is “ Borlase’s” shaft;. In the 13 fathom levels here is found the brown cellular ore, nine fathoms wide, and the analyses given are from ore taken from this level. Dynamite has been found far better than powder for blasting this “cellular” ore. “F” and “G” are also shafts sunk to prove the continuation of the lode.

The engine which is erected near “ Borlase’s” shaft is adapted both for pumping and winding. It draws the ore up a steep incline from the workings at the foot of the cliff to the summit, where a self-acting drum lowers the ore down the opposite side of the hill into railway waggons. (Courtesy of “On the Perran Iron Lode in Cornwall & The Mines in the District by Charles Parkin)

Penhale Iron Mine: Latitude & Longitude Ref: 50.378333, -5.149444

Penhale Iron Mine is known to have been at work in 1777 when it produced 41 tons of lead ore, but in common with other mines in this area it is probably much older. From this date Penhale appears to have been at work untill about 1826.

It was reopened in 1830, but only lasted a year due to the low price of lead. In 1848 the mine was amalgamated with Wheal Golden to the north, and East Wheal Golden. There was a further reworking from 1867 to about 1870. Dines records that iron ore was also worked possibly from the Perran Iron Lode. Which the Wheal Golden-Penhale lead lode must intersect with.

Recorded output: 100 tons of copper ore; 1475 tons of lead ore; 7150 oz of silver (from lead ore) & 7100 tons of iron ore. (Courtesy of mindat.org web site)

Wheal Phoenix Mine: Penhale Sands (No info) Latitude & Longitude Ref: 50.378790,-5.142541.

Reference:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 439.

Wheal Golden Mine – Penhale Point: Latitude & Longitude Ref: 50.388364, -5.154432

Wheal Golden Mine worked a nearly north-south striking lead lode extending from the tip of Penhale Point for around 500 metres southwards where the lode passes into the sett of Penhale Mine.

The course of this lode can be clearly seen in the cliffs, marked by the major gangue mineral of a comby structured quartz.

Extensive shallow workings are present on the lode and can be clearly seen in the cliffs as well.

The pumping engine house that formerly stood on Engine Shaft had a fine castellated chimney stack of the same style as that which still survives at Wheal Ellen, Porthtowan.

Unfortunately this engine house and those of the neighbouring Penhale Mine and Phoenix Mine were all demolished following a daylight air raid on the adjacent Penhale army training camp in World War Two.

Wheal Golden’s ore was noted as being quite argentiferous with considerable silver being produced along with lead. It is noted that during its working Wheal Golden was equipped with its own smelting house.

The site of Engine Shaft of Wheal Golden lies under the car park of the secure compound that lies on Penhale Point and has been plugged securely following a recent collapse. (Courtesy of mindat.org web site)

References:

Pidgeon Green Mine (Wheal Phoenix): Latitude & Longitude Ref: 50.388889, -5.149444

Pidgeon Green Mine was a small lead mine on parallel lode to Wheal Golden. Shaft dump and adit in roof of sea cave. (Courtesy of mindat.org web site)

Mellingey Mine: (No photos) : Latitude & Longitude Ref: 50.382572, -5.135756

Mellingey Mine was a small silver and lead mine, active in the early 20th century. Hamilton Jenkin indicates a shaft and an adit just NW of Mellingey farm. This area forms now part of the Holywell Holiday Park, and all traces of the mine workings have disappeared. (Courtesy of mindat.org web site)

Reference:

Ellenglaze Mine: (No photos) No Grid Ref

Ellenglaze Mine was a small lead mine, abandoned in 1839. Hamilton Jenkin indicates the portal of an adit just south of Ellenglaze hamlet, and several shafts north and NW of it. The grid reference marks a small overgrown burrow in the corner of a field, where one of the shafts was located. (Courtesy of mindat.org web site)

Reference:

A.K. Hamilton Jenkin: Annotations to Ordnance Survey map, scale 1:10,000, sheet 39SW.

Trebisken Mine (Trebisken Green Mine) (No photos) Latitude & Longitude Ref: 50.371425, -5.115326

Trebisken Mine was a small lead mine SE of Trebisken farm, working a NS-trending lode crossed by an EW-trending lode from a single shaft sunk on the intersection.

Trebisken Mine produced 861 tons of 65% lead ore and 9,190 oz of silver. Under the name Trebisken Green Mine, 7.5 tons of lead ore and 4 tons of black tin were raised in 1861. (Courtesy of mindat.org web site)

References:

Dines, H.G. (1956): The metalliferous mining region of south-west England. HMSO Publications (London), Vol. 1, p. 439 (see also addenda in the 1994 reprint).